Thermal Vaccum Rf Connection

Passive Components > Cable > Test Cable Assembly

Thermal Vacuum RF Connection

Thermal Vacuum Cables and Cable Assemblies

This cable is special designed for Thermal Vacuum Applications. The TVAC cable integrated the highest standard of materials and most strict processes in Focusimple, and has been applied to many Thermal Vacuum projects. Below is the Focusimple standard for this cable:

1. Low Outgassing. All Focusimple assemblies must meet both the NASA standards outlined in ASTM E-595 and European Standard ECSS-Q-ST-70-02 C for outgassing characteristics. (TML<1%CVCM<0 .1% )

2. Extraordinary stability of temp phase and amplitude.

3. Ultra low loss.

4. High power handling (When Power≥100W,consider multipaction )

5. Vent designing on connectors.

6. Wide temperature range. -65~+200°C

Aerospace grade connectors are also available at Focusimple:

1. Utilization of imported Ketron non-aggregate PEEK for millimeter dielectric brings following features:

1.1 Temp range: -100℃ ~ +250℃

1.2 Irradiation resistance

1.3 Flame retardant accord with UL94V-0

2. Ultilization of DAIKIN PTFE as PTFE dielectric

3. Material of screw barrel and connector body SUS316.

4 .Ultra low loss.

5. Certain portion of vent on connector body

6. Meet MIL-C-C39012

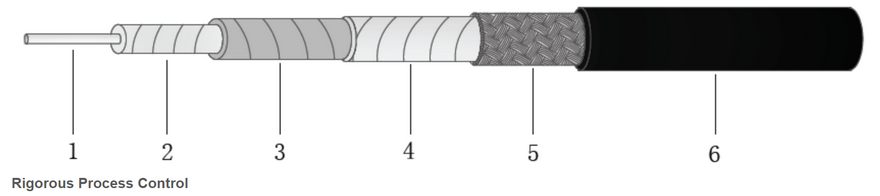

Cable Structure

1. Six layer stable structure, see next page.

2. Dielectric. Imported PTFE wrap, velocity at 82%.

3. Innder conductor, from the largest manufacturer in China

4. Interlayer. Anti-torsion layer, LD PTFE

5. Jacket. Imported material. Provide reliable protect cable from cracking at -200℃, with excellent abrasive resistance, and low friction coefficient.

1. Utilization of imported Ketron non-aggregate PEEK for millimeter dielectric brings following features:

1.1 Temp range: -100℃ ~ +250℃

1.2 Irradiation resistance

1.3 Flame retardant accord with UL94V-0

2. Ultilization of DAIKIN PTFE as PTFE dielectric

3. Material of screw barrel and connector body SUS316.

4 .Ultra low loss.

5. Certain portion of vent on connector body

6. Meet MIL-C-C39012

Cable Structure

1. Six layer stable structure, see next page.

2. Dielectric. Imported PTFE wrap, velocity at 82%.

3. Innder conductor, from the largest manufacturer in China

4. Interlayer. Anti-torsion layer, LD PTFE

5. Jacket. Imported material. Provide reliable protect cable from cracking at -200℃, with excellent abrasive resistance, and low friction coefficient.

1. Quality System: ISO9001C and IEC 966-1 followed.

2. Prepare:

2.1 Before assembly, tempature cycling is processed to eliminate internal stress.

2.2 All components will be cleaned in ultrasonic cleaners beforehand, and will be packed in anti-static bags for transferring and shipping.

3. RoHS compliance: High purity solder Sn95Ag5,

4. High Precision: SCHMIDT Assembly Instruments imported from Germany,provide precision of+/-0.02mm

5. Clean Facility: Cleaning Class 100,000 Clean Room for assembly, testing, packing.

6. Tracibility: Traceable from designing to shipment, all under control of ERP System.

Third Party Authority Quality Approval

To Guarantee the TML and CVCM meet the ATM E595-93 standard of TML<1%, CVCM<0.1%, Focusimle entrusted 5th institute of Electronics from Ministry of Industry and Information Technology - the most authoritative institute in China in this field - to do full test for us. And all results are accord with the requirements.

Multipaction - Double Protection

Definition:Dielectric material within the coaxial line could be vaporized by multipactor discahrge and generate ionized gas particles.

Consequence: In vaccum status, once such gas particle is generated, they willl float in the space between center conductor and outer conductor. When power is loaded, they will generate arc, and then spark, which could burn the connector, even damage the whole electronic system.

Double Protection 1: Focusimple designed the Complex Impedence Structure at the connector interface and cable joint, which will absolutely isolated them. An ideal struture is reallized based on electromagnetic simulation.

Double Protection 2: A certion portion of vents are designed at the connector body, so that the gas particles can be released timely.

Double Protection 1: Focusimple designed the Complex Impedence Structure at the connector interface and cable joint, which will absolutely isolated them. An ideal struture is reallized based on electromagnetic simulation.

Double Protection 2: A certion portion of vents are designed at the connector body, so that the gas particles can be released timely.